PRECIOUS METAL REFINING SYSTEMS FOR CATALYTICS

Catalytic convertors are used for controlling emissions for hazardous gases of automotive industries.

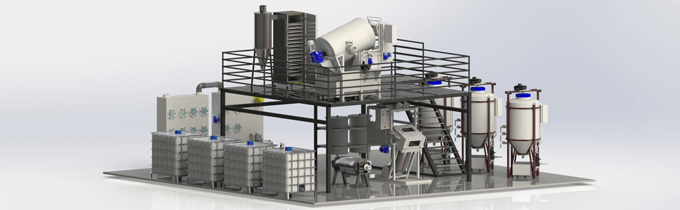

Emak developed high gain values using physical and chemical methods for turn-key facilities with variable capacities.

Advantages;

![]() Nature friendly

Nature friendly![]() Low-Cost operating

Low-Cost operating![]() Lossles process Know-How

Lossles process Know-How![]() High concentration ve efficiency

High concentration ve efficiency![]() Training and consultancy

Training and consultancy

Our patented system working in more than 50 countries and hundreds of turn-key plants.

|

CATALYTIC BURNING OVENSpecially designed for burning Catalytics. Easy to use with drawer style charging units. Capable of working with electric or gas energy. And provides a longer refracter life. The oven provides best condition to burn the dirt on the catalytic converter. |

|

LEACHING REACTORAcid Proof PP Reactor, Built-In Fume Treatment System, Built-In Precipitation System, Fast, Cheap and Easy Operation, Turn Key Installation, Complete Know – How Transfer, Adjustable for Different Capacities |

|

DECANTER CENTRIFUGEThe system uses centrifugal gravity force for separating solid and liquid phases. Unit can reach 900 RPM and has 50 Lt Capacity. |

|

CATALYTIC CONVERTER REFINING SYSTEMEcological, No harmful fumes, no smell & smoke, Turnkey of Pt, Pd and Rh from alloy or mixed dust |

|

WASTE WATER NEUTRALISATIONAfter process all waste water is transfered into the Neutralisation System. Waste Water Neutralization System is a safety point of the complete system. Because of the metal sedimentation there will be no precious metal loss with liquids. Operators can check the system efficiency in Waste Water Neutralization System. The System can be produced for various capacities. |

|

TURNKEY FIRE ASSAY ANALYSISThe oldest and most used method to determine metal’s percentage of purity is the Fire Assay (Cupellation) method.This method gives greater precision among all other methods. |

|

PL1 INDUCTION UNITEMAK’s easy to use and reliable induction furnaces works in over 50 countries. |